Professional, Commercial & Industrial Incubator Suppliers for Hatchery

- HOME

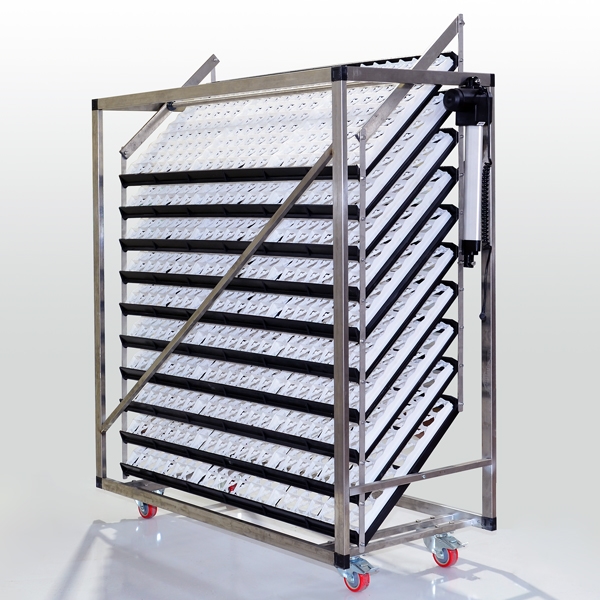

- Incubators

100% Secure Payments

Visa, Mastercard

Delivery Cost Will Change According to Postcode

Standard Delivery

2-3 working days

- Hatchers

Commercial Hatching Machine

100% Secure Payments

Visa, Mastercard

Delivery Cost Will Change According to Postcode

Standard Delivery

2-3 working days

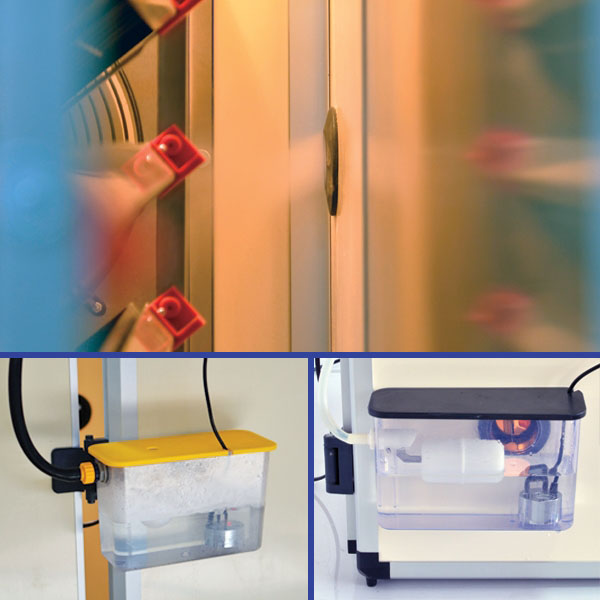

- Hatchery Equipments

100% Secure Payments

Visa, Mastercard

Delivery Cost Will Change According to Postcode

Standard Delivery

2-3 working days

- Brooding

100% Secure Payments

Visa, Mastercard

Delivery Cost Will Change According to Postcode

Standard Delivery

2-3 working days

- Accessories

100% Secure Payments

Visa, Mastercard

Delivery Cost Will Change According to Postcode

Standard Delivery

2-3 working days

- Technology

Our Technology

100% Secure Payments

Visa, Mastercard

Delivery Cost Will Change According to Postcode

Standard Delivery

2-3 working days

- Contact US